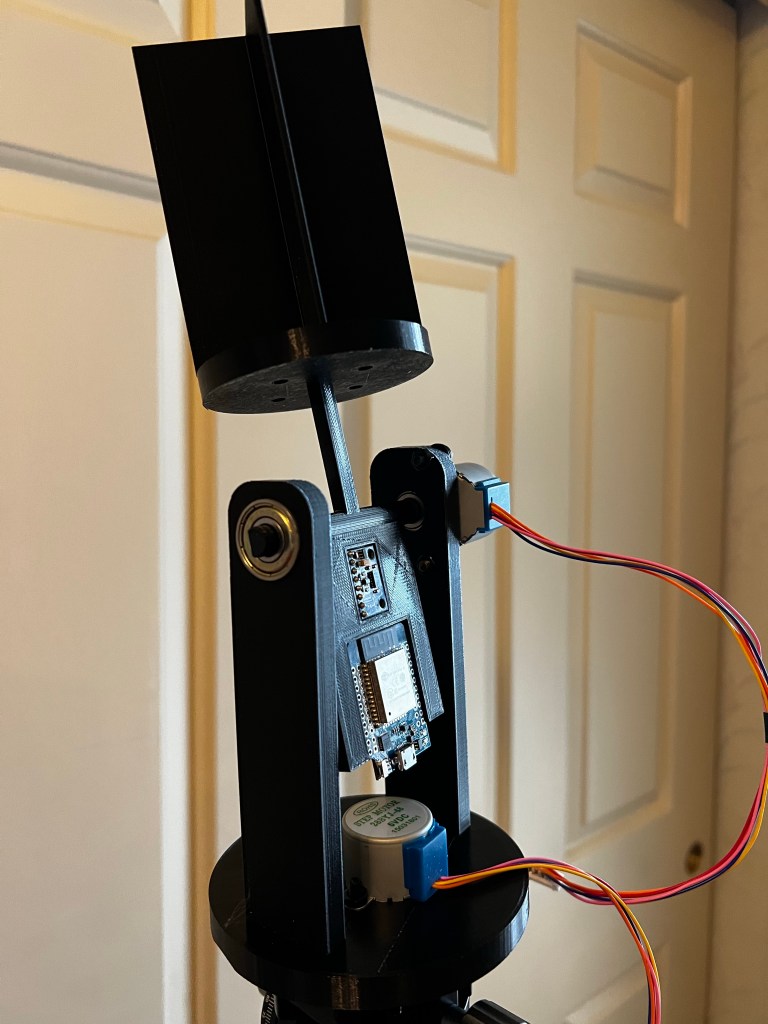

I spent a couple days fussing with the barn door tracker.

I built it according to the design, and off the bat it worked very well with my 40mm lens.

But… I wanted to use a much heavier lens, and a more demanding one.. 18-200mm at 200mm.

Ok so the first night out with it I was using probably a bad set up to do the polar alignment. The night with the 40mm lens all I did was use my iPhone compass and bubble level to line it up.. and it performed well. The night I tried the 200mm lens I used version 1 of my polar finder scope setup.

I got star trails, but that was ok, because that night I unexpectedly photographed comet in the field of view while photographing Jupiter.

So this set me off on 2 paths. One to improve the polar alignment setup, and 2 to completely analyse all the sources of error in the barn door tracker as a system, to see if it just can’t do 200mm. I talked to the designer, Peter Qun and he said, yeah.. 200mm is pushing it too hard.. it’s designed for wide angle lenses.

So I went ahead anyways to see if I could squeeze error out of the system. And there are many sources.. the camera is heavy with such a long lens, and the thing is 3D printed, so there could be flexing and twisting.. The gears are 3d printed, so definitely not perfectly round, nor probably having the hub in the center –my printer is great, but realistically…

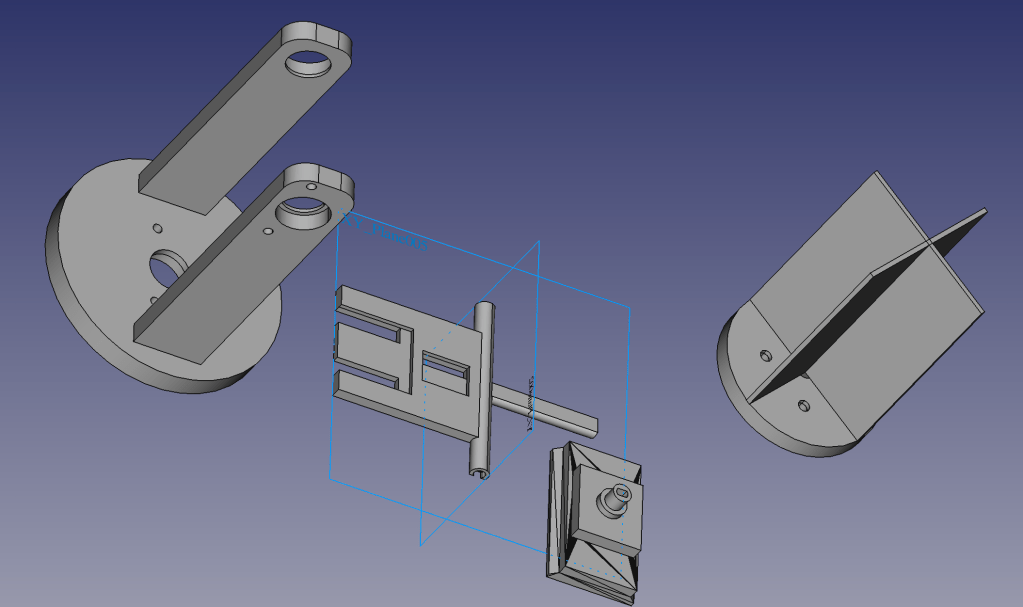

So I got this idea, put registration targets on the axel and at the end of the moving hinge, make a 16 minute video, and use Blender object tracking and some python code I wrote to read out angles every 30th of a second…

According to that it was running slow.. like 8% slow as far as angle… Then I learned that the stepper used has different versions, with different internal gear ratios… Peter’s code uses a steps per revolution figure that’s based on some people in arduino land taking steppers apart that weren’t meeting spec, and they found that rather than having a 64:1 gear reduction, it was like 63 point some awful fraction.. leading to about 2038 steps per revolution… Since I had to by 5 steppers in the package, I took one of mine apart, counted teeth and found that oops… my version really is 64:1… so I should be using 2048 steps per rev.

Well I updated the code and remeasured, and I got the error down to 3%. Since I had a lot of data, I tried to come up with an overall correction factor for angle, tried that and it did not help…

Being industrious I thought, hey… Why am I trying to make an open loop system be accurate? How about closing the loop by attaching an accelerometer module to the hinge, and read out the actual angle in real time.

Click the photo to check out the magnetometer/accelerometer I used from Amazon, buying it will also support this blog.

Oh.. Oh.. I learned a lot about accelerometer modules… They are totally noisy… But with a lot of filtering it looked like, if I set the tracker up level (not polar aligned) it did a reasonable job of stepping to the right angle at the right time, but no better really than the open loop version. Plus, though I had the math right so that the I could calculate pitch angle from the accelerometer data, even if I tipped the tracker.. I find out that at extreme angles, (such as 43.1, my latitude), the calculation for pitch angle is not reliable. Sources say, it’s only really accurate for small deviation from level.

So scrap the accelerometer, that I still have superglued to my tracker…

But this experience with angles and tilting and measuring, made me realize, that using Blender.. though it may be very accurate in object tracking, is very susceptible to the angle between my camera, and the tracker.. they’d have to be perfectly square to each other to read an accurate angle.. so scrap that idea.

So I resigned to just use it with the 40mm lens — why not? and decided to do a little upgrade.

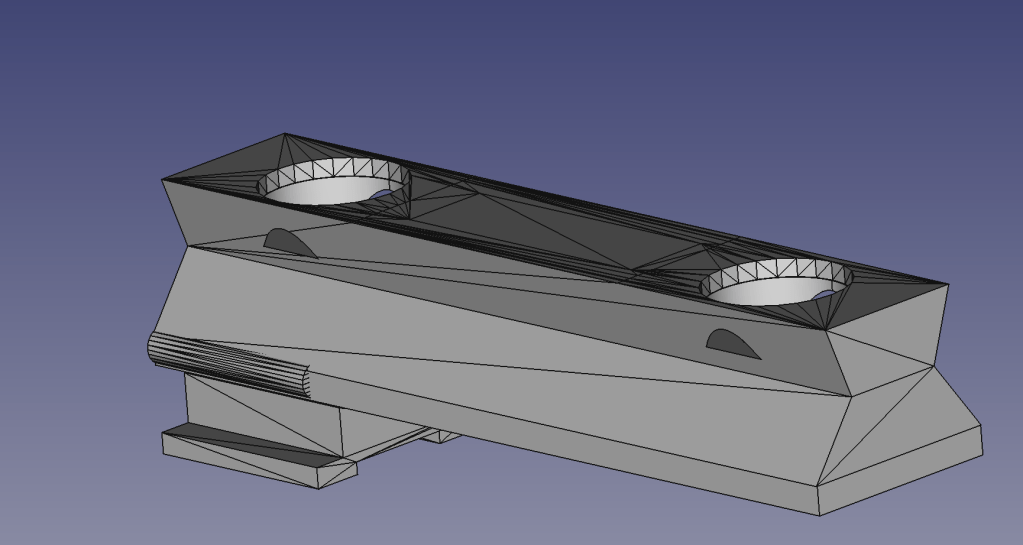

The way it’s designed, you take apart part of the tracker, manually turn the lead screw to screw the hinge fully closed, and then bolt it down.. Which is fine, you use it for an hour or two, and maybe decide to reset the thing, and manually close it to set it up again… But ever looking to make life convenient I went about adding a micro switch to the end of the hinge. And I wrote code that homes the tracker upon startup or pressing the reset button.

Click on the photo above if you want to buy the same microswitches I did on Amazon, and support my blog at the same time.

Surprisingly — That much is very repeatable… Just like a 3d printer, the code checks to see if it is already homed, if so, move it up from home a bit.. then at a relatively high speed step it down seeking the home position, then move it up just a tad so it’s just off home, and now step it down slowly to finally find a good home spot. Now there is a bit of a risk to this procedure… considering the microswitch holder and it’s pusher are 3d printed parts, if either of them break off in the processes, the tracker will probably self destruct as it crashes down never finding home. I could not think of a fail safe for this… The microswitch is normally open, you seek home until it just closes, a broken off switch will remain open.

but… Repeated measurements have it homing to the same spot within the accuracy of my ability to measure it with my calipers.

Next was to, forget Blender, and just let the system home, track for 4 minutes and stop.. allowing me to make measurements at the home position, and at the 4 minute mark, repeatedly. and also it displays how much it thought it moved the screw… After repeated measurements I get that I’m within .15mm of the desired displacement. I really can’t expect it to do any better than that. My caliper cost me about $20.. I could write a story about how measuring with a cheap digital caliper involves some guesswork.

In the final analysis… I’ll need a clear night, to do the real proof of how well it tracks.